Moving around is a primary function of most robots. Choosing which wheel to use can be a critical decision and can determine the success of a robot’s design; each type of wheel has advantages and disadvantages. The two major factors to consider are the wheel's diameter (the distance from a point on one side of the wheel to a point directly across on the other side) and its traction.

VEX V5 Wheels

This section provides a visual representation of different wheels.

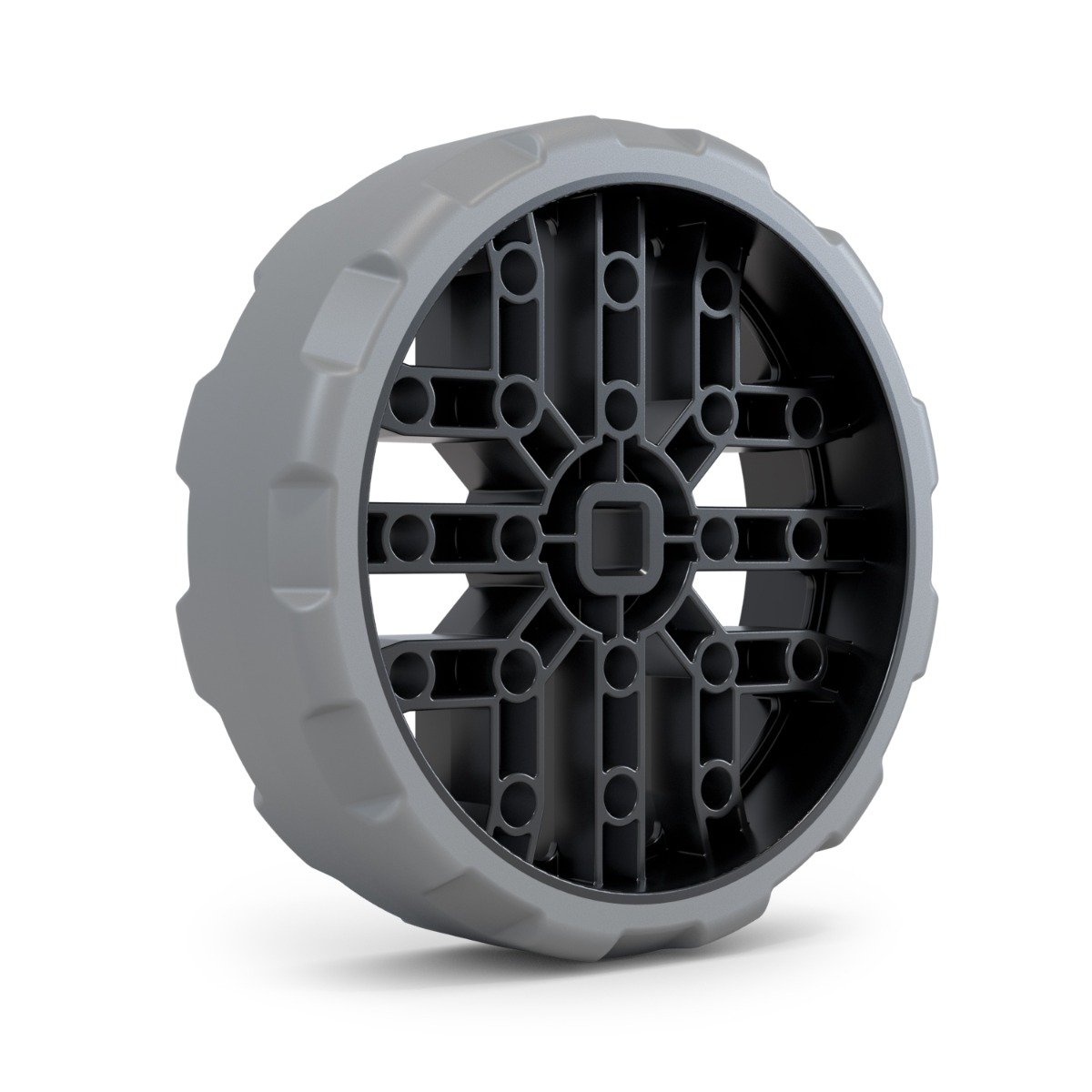

Traction Wheels

These were the original VEX V5 wheels. They are typically used in the center of drivetrains to restrict unwanted sideways movement (such as from defense). Their diameter is set up so one revolution causes the robot to travel an exact distance.

The 4'' (320mm Travel) Anti-Static Wheels are the most common wheels used on VEX V5 chassis. The 4'' (320mm travel) wheel pairs well with the 4'' (320mm) Omni-directional Wheel to make a chassis that is consistent and easy to turn.

The 2.75'' (220mm Travel) Anti-Static Wheel and 3.25'' (260mm Travel) Anti-Static Wheel are good for robots that require lower ground clearance or slower speeds. These are also commonly used for intakes.

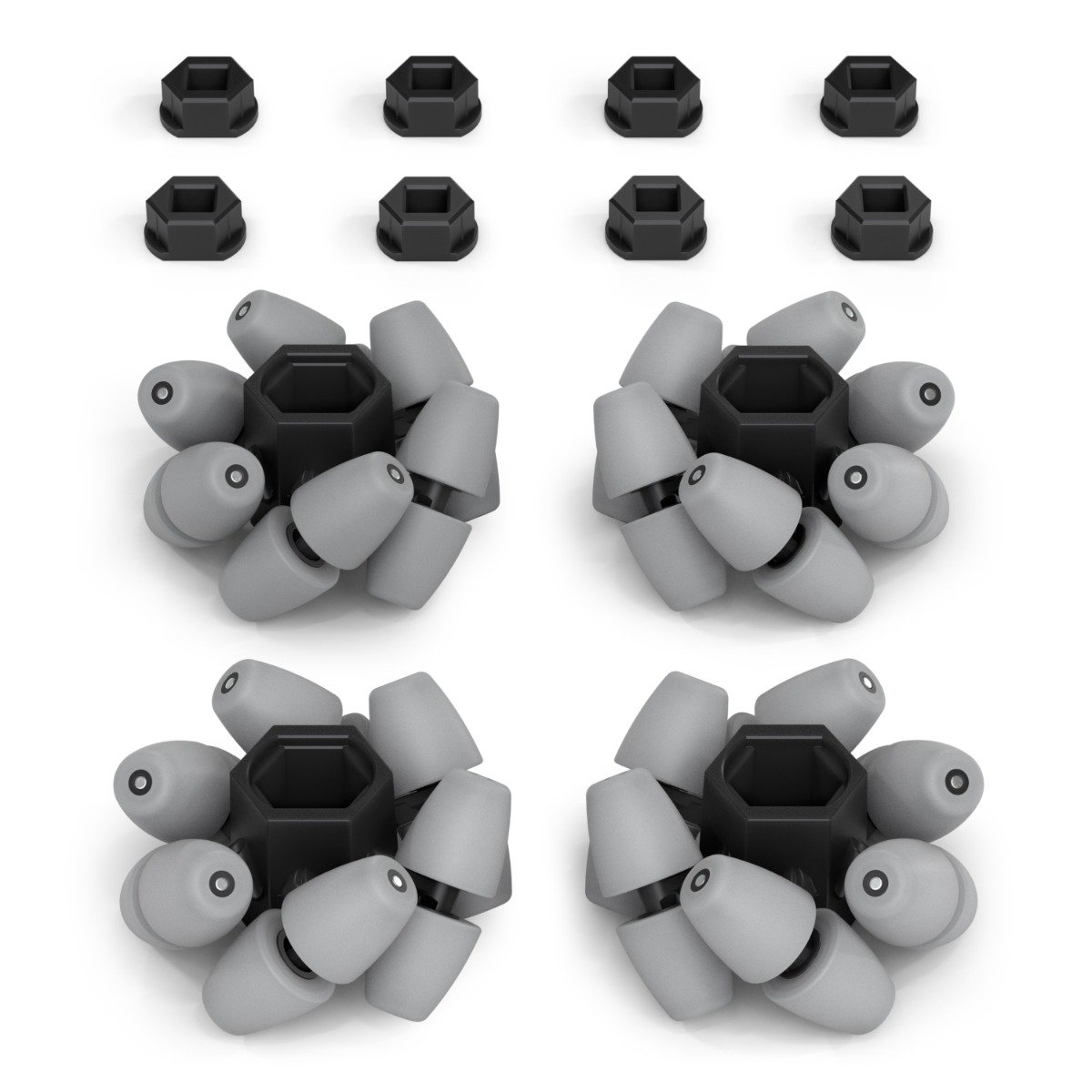

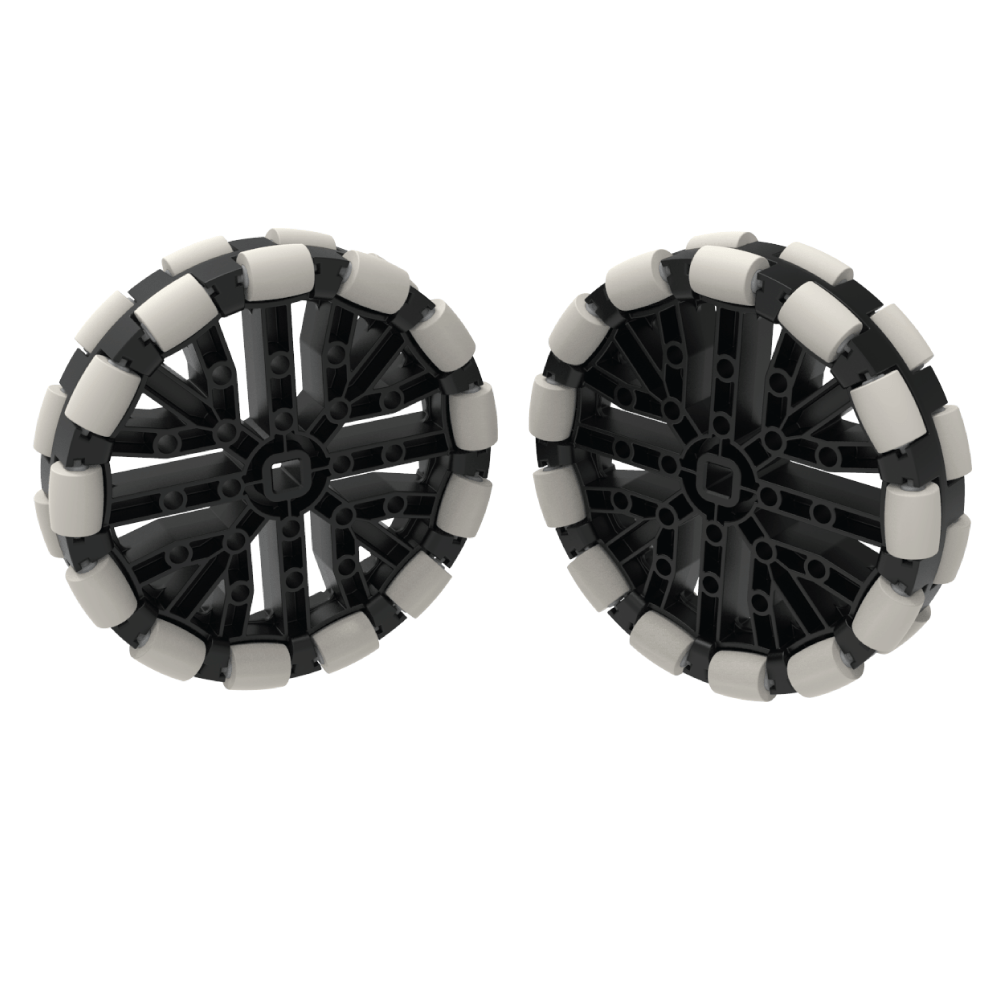

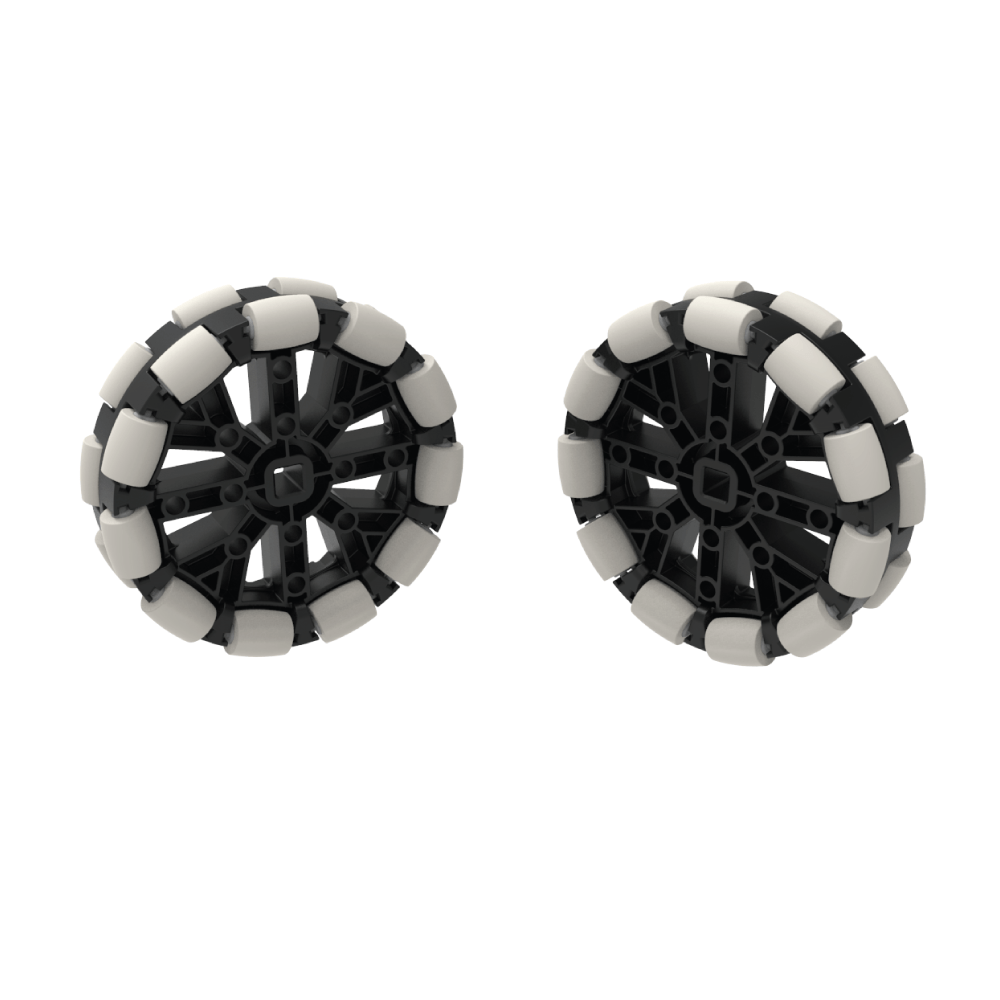

Mecanum Wheels

Mecanum wheels incorporate a series of angled rollers that constrain movement to a single axis, granting a drivetrain true omnidirectional capability. It allows the robot not only to move forward and reverse, but also to strafe smoothly without changing its orientation.

V1 2'' Mecanum Wheels

V1 4'' Mecanum Wheels

V2 2'' Mecanum Wheels

Omni-directional Wheels

The Omni-directional Wheels have a series of double-set rollers aligned around the wheel's circumference. This allows the wheels to roll side to side in addition to rolling forward and backward. Omni-directional wheels' rollers allow a robot to turn much easier than rubber tires. These are best used in combination with the 4'' 320mm Traction Wheel (for example, two omni-directional wheels and two traction wheels) to create a chassis that is level and will turn consistently.

Using special orientations of omni-directional wheels allows for more advanced drivetrain designs which can move forward/backward and side to side—omni-directionally!

Comparison of VEX V5 Wheels

| Wheel Type | Wheel Size | Distance per Revolution | Footprint | Ground Clearance |

|---|---|---|---|---|

| Omni Directional Wheel | 2.75" | 220 mm (8.66 inches) | Large | Small |

| 3.25" | 260 mm (10.24 inches) | Medium | Medium | |

| 4" | 320 mm (12.60 inches) | Small | Large | |

| Traction Wheels | 2.75" | 220 mm (8.66 inches) | Large | Small |

| 3.25" | 260 mm (10.24 inches) | Medium | Medium | |

| 4" | 320 mm (12.60 inches) | Small | Large | |

| Mecanum Wheels | 2" | N/A | Large | Small |

| 4" | N/A | Small | Large |

Diameter

The diameter of a wheel (Hub and Rubber Tire assembly) can affect a number of things.

- Distance per revolution is the distance a wheel will roll with one complete revolution, as shown in the animation below.

Footprint is the area between the points where the robot's outermost wheels touch the ground. Typically, the larger the robot’s footprint, the more stable it is and less likely it is to tip over.

Ground clearance is the height from the ground to the lowest structure on the robot. A larger ground clearance makes it easier for the robot to travel over obstacles.

Traction

The greater the traction of a wheel, the harder the robot can push or pull, and the easier it is for the robot to travel over obstacles. However, if a wheel has a high degree of traction it is also harder for the robot to turn.